How oil properties and layer thickness determine the entrainment of spilled surface oil

This study confirms that the entrainment of oil and the breakup into droplets are separate processes governed by separate parameters that can and should be included in spilled oil fate modelling.

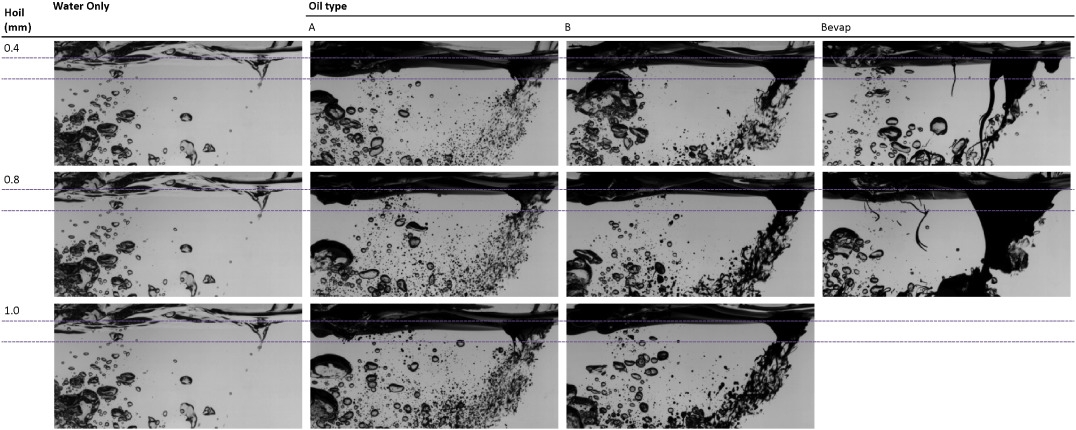

The results presented demonstrate that in most conditions, entrainment rate is independent of the oil properties. Even pre-mixing dispersants (DOR 1:200) did not significantly influence entrainment. In such cases entrainment rate at sea is simply the product of oil layer thickness and breaking wave coverage. Exception was high viscosity oil, for which entrainment was less than expected as the oil layer could not be broken up by our jet.

The influence of oil properties on the dispersion process is more pronounced in the second step, the process of droplet breakup: in our system, entrained oil droplet sizes are correlated with the Weber and Reynolds number as a result of the influence of viscosity, oil layer thickness, oil density, interfacial tension and plunge height.

These findings reveal another piece of a puzzle of understanding and predicting the efficacy and limitations of chemical dispersants application at sea.

Citation: Zeinstra-Helfrich, M.; Koops, W.; Murk, A.J. (2016) How oil properties and layer thickness determine the entrainment of spilled surface oil, Marine Pollution Bulletin, Available online 24 June 2016 http://dx.doi.org/10.1016/j.marpolbul.2016.06.063.

Data: data.gulfresearchinitiative.org/data/R1.x135.119:0001/ UDI: R1.x135.119:0001, DOI: 10.7266/N7RF5S04